✕

When it comes to simple ways to drastically improve efficiency, it is tough to beat a smart system that has integrated machine learning.

Capable of improving even older appliances with no “intelligence,” like the tried-and-true forced-air furnace, products like the smart thermostat utilize automation and data collected from sensors to optimize run times and help lower utility bills.

With how much R&D companies are investing in the newest generation of products, as one manufacturer said, if a contractor knows how to install a standard thermostat, they already know how to get a smart one connected and running, no matter if it’s a heat pump, air conditioner, or standard furnace.

AI and advanced automation algorithms are driving the phenomenal integration of smart products into both residential and light commercial buildings, and their popularity is pretty easy to understand once factoring in they can help to improve efficiency by 20% or more.

Automation, AI-Learning Taking A Bigger Role

The integration of AI into nearly every aspect of life is continuing unabated, and for HVAC manufacturers, that means the products they’re putting to market are seeing boosted efficiency and performance.

David Rames, senior product manager at Midea, said because they focus a lot on variable speed, AI and machine learning are playing a bigger role, as they can identify peak performance settings.

“We want some of that advanced intelligence to tell us where our sweet zone is for optimization,” Rames said.

This data can also help determine the correct sizing for different applications and, once a product is installed, more metrics like optimal amp ranges.

“It’s kind of like cruise control,” Rames added. “We can watch (the data) and just kind of monitor that. And then for the next cycle, we can look back and go, ‘How long did it take us to get to the set point? How long did it run? That’s where we’re going to start this time.’”

For both the comfort of the occupant and mindfulness of energy savings, ecobee is integrating automation, scheduling, and machine learning, along with the use of sensors, to achieve its goal of effortless efficiency.

SMALL SCREEN, BIG PACKAGE: The ecobee Smart Thermostat line doesn’t only tell homeowners what temperature it is, but it can also serve as an all-in-one hub for home security. (Staff photo)

The homeowner typically will establish a general schedule for themselves — when they sleep, when they’re home — then using the room sensors and occupancy detectors, ecobee machine learning can then refine equipment run-time scheduling.

“What allows us to do is optimize for comfort when people are home, and savings for when they’re not,” Adam Welton, ecobee, said. “So we’re able to claim up to 22% savings on this particular device (ecobee Smart Thermostat), 26% savings on our premium device. That’s largely a function of knowing when to roll back that temperature when the space is unoccupied.”

These systems can also prioritize certain sensors — for instance, the downstairs space would be less important if everyone is upstairs sleeping, meaning comfort can be even more optimized. Consumers can also establish important times, like when they wake up or arrive home from work, so the system can preheat or precool.

With its Sensi and Verdant products, leveraging automation to improve energy efficiency was the primary goal for Copeland. On the residential HVAC side, Sensi Touch 2 smart thermostats feature custom scheduling and geofencing controls to automate setpoint setbacks, which have been shown to deliver about 23% savings in HVAC energy costs.

ENERGY MANAGEMENT: Copeland’s Verdant line has been installed in over 6,000 hotel properties because of its ability to maximize energy savings without compromising comfort. (Staff photo)

“When activated, the geofencing feature automatically changes the setpoint once homeowners exit a predefined radius (e.g., reducing the temperature by 2-3°F during the winter) to save energy,” said Steve Stanze, director, marketing, at Copeland.

Utilizing a sub-GHZ wireless networking technology, which offers more reliable connectivity without requiring Wi-Fi, the Sensi Touch 2 and Verdant thermostats can use the autonomous Internet of Things (IoT) network.

“Up to 1,000 Verdant thermostats can be connected via a gateway to give hotel owners precise control of HVAC runtimes based on occupancy rates,” Stanze said.

“Automation plays a key role in Copeland’s production processes and product design strategies to improve product performance, energy efficiencies, and ease of use for our customers,” said Brian Knapke, director, advanced technologies, engineering and technical, at Copeland. “Copeland has assembled a global engineering team dedicated to building dynamic simulation and/or model-based tools that enable us to rapidly identify and advance opportunities to improve efficiencies.”

Over at Distech Controls, connecting people with intelligent building solutions through forward-thinking technology is helping to drive their product line and deliver smarter, safer, and greener buildings.

“We partner with customers to deliver innovative solutions that can provide better health, better spaces, and better efficiencies,” a press release from Distech Controls said. “Our passion for innovation, quality, and sustainability guides our business, which serves multiple market segments through worldwide business divisions, service offices, and a superior network of Authorized System Integrators and Distributors. Distech Controls is part of Acuity Brands’ Intelligent Spaces Group.”

SENSING MOVEMENT: Distech Controls line of Resense senors and interfaces help to cut down on utility costs by changing HVAC settings if it senses a space is unoccupied. (Staff photo)

Distech Controls Resense Move is a ceiling-mounted, AI-powered people-counting device that enhances indoor environmental quality, reduces operating costs, and provides real-time data for informed decision-making. It also helps to optimize building spaces for maximum energy efficiency and empowers businesses to make informed decisions about the operation of their buildings.

Smart Controls Getting Smarter

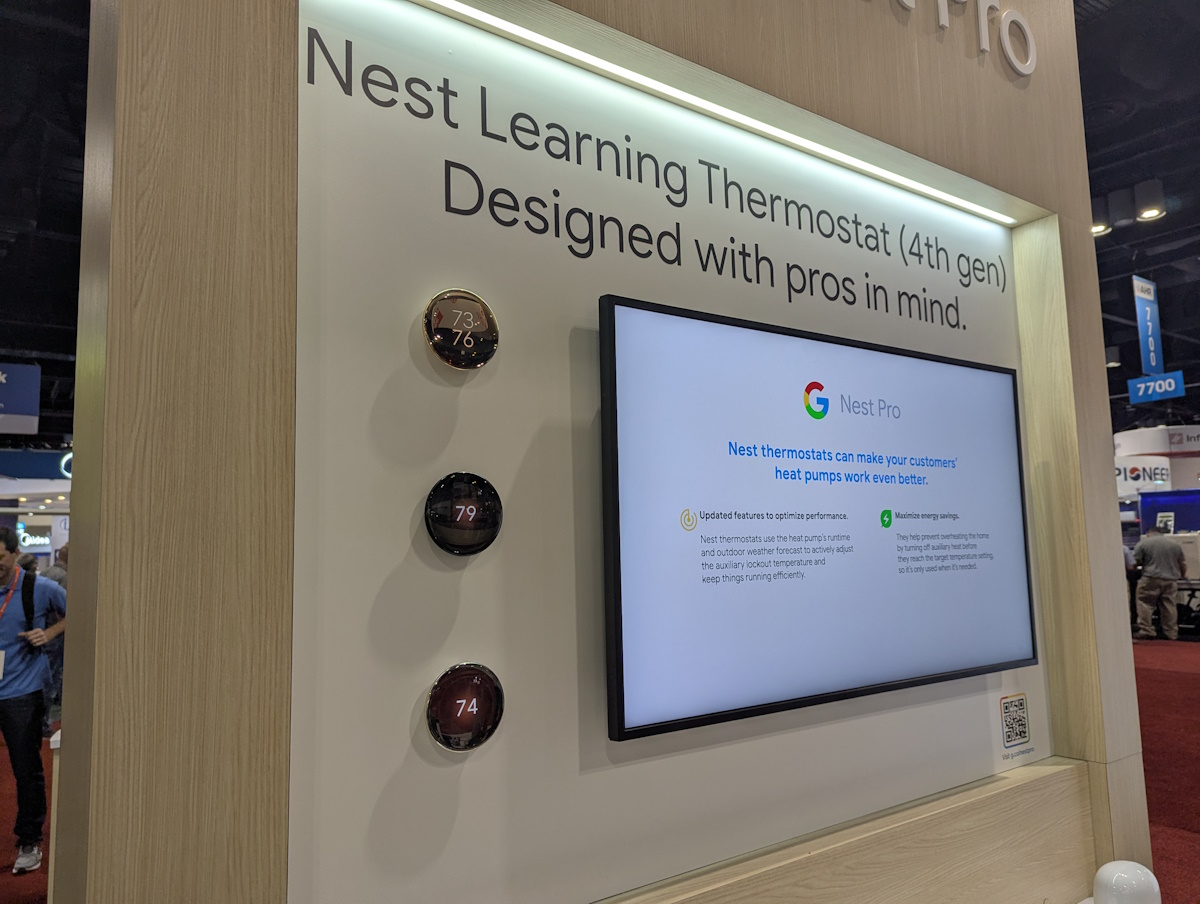

When it comes to the biggest names in AI, Google is consistently at the top of that list. While some may think of Google’s Gemini as just another LLM that can be fed random questions, it’s also being used to power the next generation of Google Nest devices.

Serge Lombardi, strategic partnerships lead at Google Nest, said their goal has always been to be helpful to the consumer, which also translates to being helpful to the pros who are doing the installations.

Launched last August, the Nest 4th Gen is a learning thermostat that gives customers more controls, and makes things easier on the pros by being easy to install, customize, and connect to other devices.

“A lot of what we do is going to be how we integrate us across platforms,” Lombardi said. “Gemini, longer term, will be a big part of that story, and how we can talk to products within the smart home.”

ALWAYS LEARNING Google Nest thermostats are constantly gathering data to optimize runtimes and lower energy costs. (Staff photo)

Welton described ecobee as utilizing more machine learning, where it can recognize patterns and behavior, and then leverage that data to enhance efficiency. For instance, it’s difficult to go in and create a seven-day schedule, because life is more dynamic than that, but ecobee can take that data and build off existing data and refine that schedule.

Copeland has integrated variable-frequency drives, paired with its modulating compressor platforms, to leverage intelligent machine-learning algorithms to fine-tune compressor operation based on ever-changing conditions.

“These algorithms help to maximize the performances of compressors and drives throughout the modulation range — over-speeding to increase capacity when needed while operating reliably and efficiently at lower speeds,” said Kashmira Patel, director, engineering, engineering, and technical at Copeland. “As a result, consumers can expect year-round efficiency and seasonal comfort in their air conditioning and heat pump systems.”

Copeland’s onboard compressor electronics module provides performance optimization, protection and seamless control system integration.

“From a product functionality standpoint, it offers compressor fault detection and protection, increasing application reliability for end users while giving technicians the information they need to accelerate issue resolutions in the field,” said Patel.

Reports from the Field

What’s promised on paper can often be a little different than what’s being experienced in the field, but luckily for contractors, manufacturers putting out products with automation features are standing behind them.

Rames said they’re hearing contractors want more automation and smart products, but they also want more training.

At Midea, Rames said they train all of their distribution partners, but they take it a step further.

“When we have a training session for say, 25 people from our distributor partners, we want them to call in their contractors, too,” Rames said. This helps to alleviate any concerns contractors might have about installing these products.

Contractor feedback is everything to Midea, Rames said, and they even play a huge role when it comes to developing products.

Five years ago, when he was tasked with developing the commercial units, Rames started with five of his contractor friends, a very rough prototype, and three competitive units.

“I said bring your tool bags — we’re going to take them apart and put them back together, and we’re going to film it, and you’re going to help me develop the industry’s easier air handler,” Rames said.

Rames said he knows it’s a good product if it’s covered in contractor fingerprints.

FOR THE PEOPLE: While most contractors are asking for more products featuring automation, Midea said they’re also asking for more training, which Midea provides in a number of ways. (Staff Photo)

“We always take the contractor/consumer into play, and then we’re a little different, because we’ve got this huge group of engineers, but I don’t want to just create a product and force feed (a new product) on the distribution, contractor, and homeowner,” Rames said. “So we spend hundreds of thousands of dollars in consumer research every year. The consumer and contractor? Let’s see what they want and then push it up. That’s my innovation process.”

Nest’s reception from contractors and users has been overwhelmingly positive, and it now has a broader array of applications it can be used for.

“It’s going to do certain things that’ll allow you to more intuitively adjust your thermostat, lowering the temperatures during peak load times or raising them during peak load times,” Lombardi said. “So you’re saving energy. And also, the new Eco modes are also available here as well.”

For ecobee, any move they make takes into account the pro that has to do the installation, which is why they utilize industry-standard connections.

“So if a contractor has installed a thermostat on conventional equipment, a heat pump, they know how to do it here,” Welton said.

When connecting to heat pumps, Welton said the menu will walk contractors step-by-step through the process, with question prompts along the way.

“So for the installing contractor to get through installation, to get the equipment and tested and run, everything should feel very intuitive,” Welton said. “and then the homeowner can kind of take over and has that whole smart home experience.”

Copeland places a high priority on making sure contractors are supported with the tools they need in the field to improve service efficiencies, including their mobile app, Scout, and AI chatbot, which gives access to documents, videos, product and warranty information, and other resources, while also helping to troubleshoot and retrieve specs in real-time.

“Its integrated scanning feature lets technicians scan a Copeland barcode and pull up its specifications quickly, providing diagnostic support and detailed service and maintenance documentation,” Julie Walters, director, aftermarket, at Copeland, said. “Scout AI is self-learning, enhancing access to information and streamlining interactions to help contractors complete tasks more efficiently and accurately.”

Sensi also has a companion app that enables contractors and end users to set up and manage their HVAC controls quickly with an intuitive interface.

Distech Controls has launched several new products in the sensors and interfaces space, including the award-winning Resense Move. Distech Controls has been collaborating with university researchers who do deep dives in certain areas and the company has utilized those findings to understand what is going to work for their market.

The AI technology incorporated into Resense Move has proved to be beneficial for numerous stakeholders — for instance, end users benefit from enhanced well-being and proactive ventilation, while facility managers can optimize their buildings and deliver proactive maintenance, such as fault finding.

Where Trends, Demand Go from Here

While there are always late adaptors, most homeowners are now extremely interested in products that are intimately connected and can be easily accessed.

Lombardi sees the future as having more interoperability, especially because the Google Home platform is pretty universal and plays well with third-party products. By basically operating off a single platform, that makes things more accessible for consumers and pros.

But when designing this fourth-gen product, Nest put increased focus on features for the pros, like the applications for heat pumps and ERVs, things the consumer might not be interested in or even aware of.

The smart thermostat is one of the most penetrating smart home devices, Welton said, and energy savings will still likely be at the core of that in the coming years.

“Energy prices are going up, so you need to optimize how you run the equipment,” Welton said. “A lot of older equipment, even new equipment that is not communicating, has no intelligence in it, and this has intelligence in it.”

Aside from energy savings, the remote monitoring aspect will play to consumers, and that blends into these advanced smart systems integrating more features into the overall experience. Ecobee’s equipment can merge the video doorbell and even sensors that can alert if a door or window is left open (and then cut the HVAC, if prompted), all into one mobile app. There are even options where the status of a standby generator can be monitored in that space, too.

For the smart industry, the biggest point of dissatisfaction is interoperability, but that’s where premium products and their ability to connect will differentiate themselves.

“We believe as a business that there’s this really nice intersection between energy and monitoring and security. And so what we’ve allowed to do is take this thermostat and extend it to making all the way to sort of a hub for security,” Welton said. “And so try to take these devices and extend the value proposition to them, and keep it very simple for the homeowner, and drive high interoperability.”

With tools like Generac, there’s compatibility with all the large platforms (Apple, Google, Amazon).

Welton also sees this evolving past just being a “smart product” and more into the home energy management sphere.

Copeland sees the heat pump/smart controls combo as a strong solution to the heating capacity requirements and ever-stricter efficiency standards situation.

The new Sensi Equipment Interface Module (EIM) is designed with enhanced connectivity to simplify HVAC upgrades, heat pump installations, and retrofits, while also leveraging Sensi Connect to enable communication among the module, Sensi Touch 2 smart thermostat, and indoor and outdoor sensors.

“It eliminates the need for contractors to pull additional HVAC wiring to the thermostat while enabling the Touch 2 smart thermostat to manage IAQ through three universal terminals for humidification, dehumidification, and ventilation,” Stanze said.

Rames said just the simple fact that standards are getting so difficult to meet likely means automation features are going to be in everything in the coming years.

“As a matter of fact, there’s a new standard coming that if you call your system a variable-speed system, it can’t stop, so it’s got to run all the time,” Rames said. “But if you think about it, if it runs all the time, and we can use AI to find that sweet spot, then it can run all the time, and it doesn’t have the amp drop, ON-OFF, ON-OFF, ON-OFF; most of the amperage just pulls, stops.”

With 80% of the systems in the field being oversized, the set point is reached too quickly, which means more start/stop and therefore, more energy usage and less comfort.