As contractors and technicians cope with packed work schedules, a shortage of skilled labor, and increasingly complex HVACR systems, they welcome anything that helps them get their jobs done better, faster, and easier — and that perhaps brings in more revenue, too.

At last month’s AHR Expo in Orlando, Florida, companies from manufacturers to toolmakers touted the ways in which their products assist those who maintain and repair HVACR systems. Whether it’s the technician-friendly features on Daikin Applied equipment or the disinfection product, D7, from Decon7 Systems, which offers contractors a new revenue stream in system maintenance, products are being designed with technicians in mind.

Milwaukee Tool

Products in the pipeline at Milwaukee Tool will add to its already sizeable lineup of tools and accessories for HVACR technicians.

Coming later this year are several additions to the company’s Packout storage system, a line of toolboxes, racks, holders, toolbags, and other gear that help technicians keep things organized in the shop and the truck. The modular design of Packout gear allows techs to build customizable storage solutions, with interchangeable components, that meet their individual needs.

Among the products slated for introduction in the third quarter is a Packout rack kit that can be mounted in a work van. The kit keeps tools, accessories, and small parts secured while techs are on the road. Also on the way are a 366-piece mechanics tool set with Packout drawers, a 64-piece hand tool set in a four-drawer toolbox, and a 242-piece SAE and metric socket and ratchet wrench set, also in a four-drawer toolbox.

Coming next year is an addition to Milwaukee’s cordless tool lineup, a brushless refrigerant recovery machine that uses the M18 (18-volt) battery that powers many of the company’s tools.

“For our users, that’s a big advantage, because they have a lot of those packs already,” said Riley Peterson, an associate product manager.

The machine is compatible with A2L refrigerants, has an adjustable automatic shutoff to guard against contamination and a self-purge feature, and weighs 24 pounds. Peterson said it will be the first cordless recovery machine in the industry.

The recovery machine, Peterson said, will be a companion to Milwaukee’s cordless M18 Fuel 5 CFM vacuum pump, used by techs when refilling refrigerant systems. The M18 Fuel 5 CFM, also A2L compatible, is already available.

Later this year, Milwaukee will offer pivoting rings for its Streamline ACR press tool system. The rings will allow techs to make press connections on refrigerant lines in tight spaces where they might not be able to hold the tool perpendicular to the piping.

Decon7 Systems

Decon7 Systems Inc. wants to add to contractors’ and technicians’ workloads — in a good way that adds value and brings in revenue.

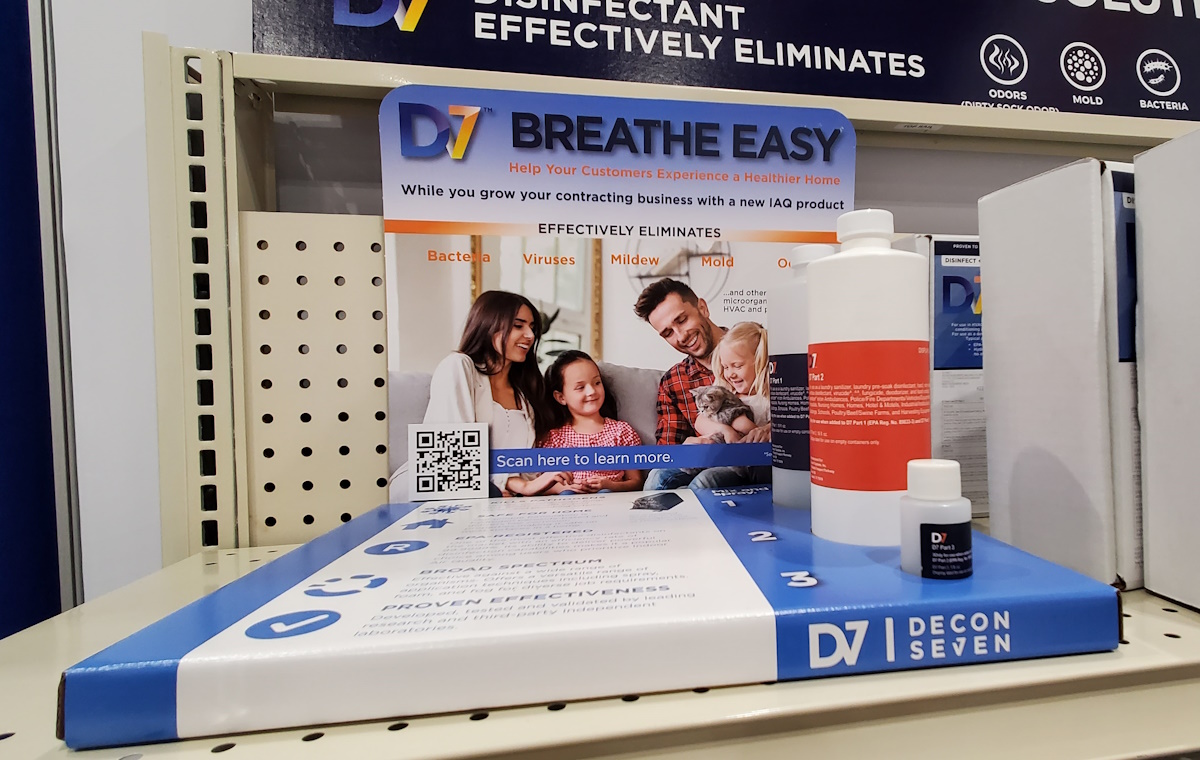

The company’s D7 product is a spray-on disinfectant for major HVAC components, including evaporator coils, condensing units, and drip pans, that kills mold, viruses, bacteria, and other pathogens, making HVAC systems cleaner and improving IAQ. D7 also destroys allergens and, when fogged into ductwork, acts as a deodorizer.

KEEP IT CLEAN: The D7 disinfectant product from Decon7 Systems comes in volumes ranging from a four-quart kit, shown here, to 510 gallons. The smaller size is enough for a typical residential HVAC system. (Staff photo)

Because of their exposure to airborne contaminants and moisture, HVAC system components can be a favorable environment for contaminants. But many don’t think of disinfecting that equipment, despite its presence throughout a home or business.

“You disinfect every single thing in your home except the one area that touches your entire home, and that’s your HVAC system,” said Ira Copeland, vice president of marketing at Decon7 Systems.

D7 can remedy HVAC’s dirty sock syndrome, the smell that wafts up when an a/c system with a contaminated evaporator coil is turned on, Copeland said. It’s even effective on contaminants like mice droppings and roach droppings, she said. D7 can also be used, as directed on the instructions, to disinfect sinks, showers, bathtubs, and washing machines.

D7, Copeland said, is comprised of water, hydrogen peroxide, a surfactant, and “secret sauce” ingredients that make everything work together. Technicians should wear gloves and safety goggles when applying but, “unlike a lot of the other chemicals that are on the market,” Copeland said, “you’re not going to go to the emergency room if you get it on your skin.”

D7 is available in sizes ranging from a four-quart kit, which Copeland said is enough for a typical residential HVAC system, to bulk volumes of up to 510 gallons. It’s recommended to be applied to HVAC systems twice a year, which, Copeland said, meshes with the biannual system checkups that contractors offer.

The product offers contractors an inexpensive way to move into IAQ work, Copeland said, and add value to their brands.

D7 has been extensively tested and is recognized by the U.S. Environmental Protection Agency (EPA) as 99.9999% effective as a disinfectant — and those four nines to the right of the decimal point are not just for marketing purposes. They mean the product is actually effective to that extent, Copeland said.

“To become EPA-registered as a disinfectant is a long and very expensive process,” she said.

Daikin Applied

Ease of maintenance starts with product design, said Jim Macosko, vice president of product and sustainability solutions at Daikin Applied.

“We’re all about the maintenance side,” Macosko said at Daikin Applied’s display at Orlando’s Orange County Convention Center.

Enter products like Daikin’s Vision air handler, a flexible air handler in capacities from 900 cfm to 100,000 cfm that can be built to fit most footprints and works well in smaller mechanical rooms.

The Vision is customizable, Macosko said, in 2-inch increments in width and height, making it a flexible fit for equipment replacements.

ROOM TO WORK: The flexibility of Daikin Applied’s Vision air handlers means they can be built in a way that gives technicians comfortable access to interior components for cleaning and servicing. (Staff photo)

“This product is designed so that it can easily be sized to fit the existing space,” he said.

The customization feature, he said, also makes it easy to build the Vision so that technicians have easy access to the interior for routine cleaning and maintenance.

The Vision operates with high efficiency and low noise, the company said, and can improve IAQ with the use of sorbent filtration that removes CO2, volatile organic compounds (VOCs), and other contaminants while allowing oxygen and water to pass through. When used with the ASHRAE 62.1 IAQ procedure, the technology offers the air changes recommended for healthy indoor air, meaning operators can decrease the amount of outdoor air they need to bring in.

The Vision also has IAQ options like UV lighting, a mold-resistant drain pan, and an antimicrobial liner. There are also fan, filtration, coil, and energy-recovery options.

Daikin’s Magnitude water-cooled, oil-free centrifugal chillers are also designed to be easy on technicians, Macosko said.

The chillers’ compressor shafts float on magnetic bearings rather than relying on oil to reduce friction.

“Taking the oil out of the system eliminates the need for a lot of maintenance,” Macosko said.

Magnitude chillers have two-stage compressor technology, which results in energy savings of up to 40% over fixed-speed compressors, the company said. The compressors in Magnitude chillers are equipped with two impellers, Macosko said.

Chillers in the Magnitude line are available in capacities from 86 tons to 1,600 tons, and are suited for a range of building applications, the company said.

“As long as you keep your water system clean, there should be very little maintenance,” Macosko said.

RectorSeal

RectorSeal offers an array of products that help keep HVACR equipment in top shape and make the technician’s job easier.

There’s the Cool Braze heat shield, a Play-Doh-like substance that protects adjacent components when copper or brass tubing is being brazed or soldered. Cool Braze wraps tightly around the parts to be protected and can be reused again and again.

“It’s much more effective and safer than wet rags,” said Sean Holloway, a RectorSeal product analyst.

CONDENSATE MANAGEMENT: RectorSeal’s Safe-T-Switch line includes cutoff switches to protect against HVAC condensate system leaks, and cleanout ports that makes it easier to clear clogs. (Courtesy of RectorSeal)

There’s also Better Bubble leak locator, a high-viscosity fluid designed to pinpoint the tiniest refrigerant, gas, and air leaks by producing well-defined bubbles when a leak is found. “Sometimes a really small leak won’t manifest too well,” when traditional leak-detection fluid is used, Holloway said.

RectorSeal also has the Calci-Free flush kit for tankless residential water heaters.

“Tankless water heaters are very susceptible to calcification, and you lose the efficiency,” Holloway said. Calci-Free should be used on tankless residential water heaters once a year, he said.

RectorSeal introduced its GulfCoat corrosion-protection coatings about a year ago, Holloway said, to protect outdoor HVAC equipment from harsh environmental conditions, such as high humidity or the sea spray found in coastal regions. GulfCoat, available in blue or clear, offers resistance to moisture and UV rays, limits dirt and debris buildup, and extends equipment life, the company said.

There’s also GulfCoat Circuit Shield, a spray-on acrylic coating that protects circuit boards in outdoor equipment.

“These boards are very sensitive. A lot of the industry is finding this out,” Holloway said.

Then there’s RectorSeal’s ClearDrain PVC, zinc-infused PVC piping with a distinct green color and a smooth, hydrophobic inner surface that protects against the buildup of bacteria, viruses, molds, and other contaminants that can infect and block HVAC condensate lines.

The use of ClearDrain PVC can help avoid condensate overflows and the water damage to walls, floors, and ceilings that condensate leaks can cause, the company said. Without precautions, Holloway said, untreated condensate lines in humid regions can clog up in less than a year.

For further condensate system protection, RectorSeal offers its Safe-T-Switch products, condensate overflow cutoff switches, and in-line cleanout ports that give technicians access to condensate piping in order to easily clear it out. One Safe-T-Switch model features a Schrader valve connection so that compressed air can be used to blow out debris.

Malco Tool

At Malco Tools Inc., it’s the details that make a difference. Malco offers a line of HVACR tools in which small features, such as a spring-loaded magnet on a nut driver, or a pair of snips with offset blades, can translate into time and trouble savings on job sites.

The latter product, Malco Vertical AVs (aviation snips), comes with full-sized blades set at a 90° angle to the handle, making it easier for techs to cut sheet metal overhead or in tight places, said Jon Olson, a Malco product training manager. The Vertical AVs are available with right- or left-oriented blades and can cut through cold-rolled steel of 24 ga. maximum (28 ga. for stainless steel).

THREE IN ONE: Malco Tools Inc. offers a multipurpose tool for working with flex duct that combines a duct knife, a wire cutter, and a zip-tie tensioner. (Staff photo)

Malco’s Mini AVs also give techs an edge in tight spots: At 7⅛ inches long and 8 ounces, they’re more than 2 inches shorter and 6 ounces lighter than standard Malco snips, and thus easier to carry and use in attics and crawl spaces.

“A lot of people are not wanting a full-sized snips when they go into a crawl space or somewhere tight where they really don’t have room to work,” Olson said. The Mini AVs can also cut up to 24 ga., 28 ga. for stainless.

Malco also has its “blue line” of color-coded nut drivers with spring-loaded floating interior magnets, which allow techs to use fasteners with longer head sizes and make for stronger magnetic connections between the bits and the fasteners, Olson said.

Blue line drivers, Olson said, are designed to withstand repeated use with impact tools, which techs might use, for example, when securing outdoor equipment to a concrete pad. The floating magnet allows the recoil from the use of an impact tool to dissipate, saving wear and tear on the driver.

“If you contact that magnet continuously, you’re going to transmit that force into the magnet,” Olson said. “That may damage it, whereas our impact blue line, it has the spring-loaded magnet, and that is going to accept a variety of different head heights, and it’s going to allow it to retain that magnet for many years.”

Malco also has a line of tools for flex duct, a duct material that Olson said is fast gaining popularity.

The FDC3 Flex Duct Tool, he said, is a three-in-one: a duct knife, a wire cutter, and a tensioner for securing zip ties on flex duct. The TY6 Tie Tensioning Tool lets a tech choose the exact tension for each zip tie, then cuts off the tie’s tail once that tension level is reached.

“It’s going to cut the tie for you, and you’re going to be able to know, ‘I set that to the correct tension, and I’m ready to move on to other tasks,’” Olson said.