✕

Estimates vary, but it’s widely acknowledged that HVAC systems in buildings — residential, commercial, industrial, institutional — together account for a significant proportion of greenhouse gases, which contribute to global warming and climate change.

Accepting this, HVAC manufacturers have embraced the building electrification and decarbonization movement. This is an attempt to, over the next couple of decades, move HVAC systems away from burning fossil fuels and toward higher-efficiency systems that use electricity but keep building occupants, even those in the coldest climates, at least as comfortable as they were with natural gas- and oil-burning systems. Parallel to this is a movement to increase the use of renewable energy sources, like wind and solar power, to generate electricity, though it must be said that roughly 60% of the electricity in the U.S. still comes from burning natural gas and coal.

To understand the trend better, on the HVAC side of things, The ACHR NEWS visited manufacturers during the recent AHR Expo in Orlando, Florida, to ask about products suited for electrification and decarbonization. Here’s what they had to say.

Copeland

Copeland makes the compressors at the heart of the equipment, such as chillers and heat pumps, that’s on the leading edge of the electrification trend.

The company has vapor-injection scroll compressors, for example, that can operate at an ambient temperature down to -25°F, said Steve Hueckel, senior marketing manager and global data center lead at Copeland. They’re a good fit for commercial HVAC equipment that has to withstand extreme, extended cold weather.

“That gives us a solution to provide for end users, for OEMs looking to be able to offer an electrified solution,” Hueckel said. Both fixed- and variable-speed models are offered.

Copeland vapor-injection scroll compressors are being used in modular heat-pump chillers, Hueckel said, that are replacing fossil-fuel-burning boiler systems in older buildings in the Northern U.S.

OIL-FREE COMPRESSOR: Copeland’s oil-free centrifugal compressor with Areo-lift bearing technology. The compressor shaft floats on a layer of gas, a technology that eliminates the need for magnetic bearings or oil. (Staff photo)

“Because you can get that modular chiller … through that doorway, it makes replacing some of this legacy stuff, like in New York City, a lot easier,” he said. “So that’s one of the areas we’ve seen the modular chillers in North America really making some headway and penetration in terms of electrification.”

Modular chillers can be stacked to increase capacity, and connected to a building’s existing system, making retrofits less intrusive than they might be with other technology, Hueckel said.

“We’ve got other OEMs we’re working with (for) the larger package heat pumps,” he added. “These would go, perhaps, up on the roof, and would also provide either hot air or hot water for the building.”

Copeland also makes an oil-free centrifugal compressor with trademarked Areo-lift bearing technology, which has the compressor shaft rotating on a layer of gas, eliminating friction without the use of magnetic bearings or oil. It’s designed for use in air- or water-cooled chillers for data centers, healthcare facilities, and other buildings where large chillers are needed.

“This is a great product for, say, if you’re running a chiller and you want to use heat recovery, you want to be able to recapture some of the waste heat and then recycle it back into the chiller and be able to use it for hot or cold water,” Hueckel said.

Copeland has compressors for residential HVAC, too.

“The big advantage with these products is … you can make great heat pumps,” said Josh Souders, a Copeland product marketing manager.

The compressors come in fixed-speed, two-speed, and, like the YAW vapor-injection model, variable-speed versions.

“When you start getting into those modulated technologies, of which variable speed is one, that gives you a lot of flexibility to get more efficiency out of the system when you don’t have really high demand,” Souders said.

Midea America

Midea America Corp. is helping smooth the decarbonization and electrification pathway with efficient residential products that perform in cold climates, fit a variety of installation scenarios, and offer controls that meet precise user preferences, according to David Rames, a senior product manager.

“I always say: Grandpa’s heat pump, at 40°F, people froze to death, right?” Rames said. “And that’s why heat pumps, early on, got a terrible name. But now we’ve changed them.”

Rames might’ve been exaggerating a bit, but heat pumps have come a long way in recent years in providing adequate indoor heat in below-freezing outdoor temperatures.

Midea’s Evox G3 heat pump system is rated to provide 100% of its capacity at an ambient temperature of -15°F — and actually delivered 118% of capacity at that temperature, Rames said. The inverter-compressor-driven Evox G3, for ducted systems, is available in sizes ranging from 1.5 tons to 5 tons and has efficiency ratings of up to 19 SEER2 and 10.8 HSPF2.

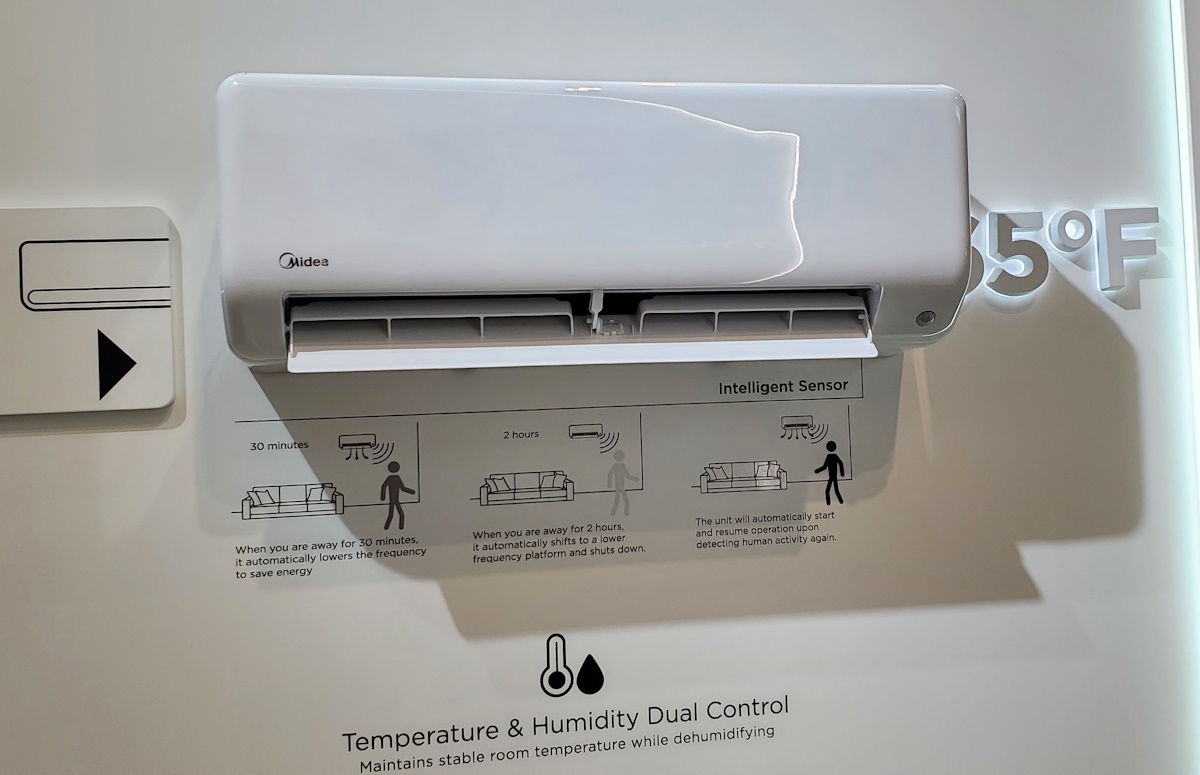

PRECISE CONTROL: A Midea All Easy Pro high-wall indoor unit for a ductless system. The unit offers humidity control, precise louver adjustment, and a motion detector, and automatically lowers its operational frequency once a room has been unoccupied for 30 minutes. (Staff photo)

“Because of the heat we’re putting out with our heat pump, you don’t really even need an auxiliary heater — 90% of the areas in North America won’t even need an auxiliary heater,” Rames said.

Installed with a Midea air handler, the Evox G3 can be used as a direct replacement for a gas furnace. To make installation easier and less expensive, Rames said, the system has a multi-voltage feature that automatically recognizes either 115V — the voltage of the typical residential natural gas furnace — or 208/230V, and can adapt to either, eliminating the need for electrical panel upgrades.

In its ductless lineup, Midea has equipment that can heat and cool up to six zones; the indoor units can be ceiling cassettes, high-wall mini-splits, or low-mounted wall units that fit spaces with lower-than-standard walls, such as in attics under sloped roofs. Midea also has the Advantage Series air handler, which can be used in ducted/ductless combination systems.

The All Easy Pro high-wall indoor unit is the best seller, according to Rames. Available in sizes from 0.5 ton to 3 tons, the All Easy Pro has a motion sensor, a humidity sensor, a detachable wind wheel for easy cleaning, and quick access to the evaporator

The All Easy Pro can sense the movement of a room’s occupants, Rames said, and blow conditioned air where the occupants prefer, either directly at them or away from them. It’ll also automatically reduce its operating frequency, in order to save energy, when a room is unoccupied for 30 minutes or more.

Danfoss Climate Solutions

Computer data centers generate enormous amounts of heat and require consistent, reliable cooling to protect banks of sensitive servers and keep them running smoothly.

And with an increasingly computer-dependent society that’s only starting to discover the possibilities of artificial intelligence (AI), data center planners and builders are keeping busy, and massive, campus-like data centers shared by several providers are becoming more common.

Danfoss makes a variety of products for both air-cooling and liquid-cooling systems in data centers, as well as equipment that can harness their waste heat, directing it to district heating, for example, said Anthony McRay, director of business development for global data solutions at Danfoss Climate Solutions. This furthers decarbonization efforts by more efficiently cooling data centers as well as by using waste heat instead of releasing it into the atmosphere.

COOLING SYSTEM BRAINS: A Danfoss-branded cooling distribution unit, or CDU, which manages the cooling in a data center and sends it where it needs to go. Danfoss makes about 90% of the components for CDUs, a company spokesman said. (Staff photo)

The company provides components that include fan drives, balancing and control valves, condensers, evaporators, inverter scroll compressors, and customizable heat exchangers.

Danfoss, McRay said, also makes about 90% of the components needed in a CDU, or cooling distribution unit. A CDU is the brain of a data-center cooling operation, managing the cooling the system provides and sending it where it needs to go for optimum efficiency and data center operation.

Danfoss equipment, McRay said, can be used in a data center’s free cooling system, which uses naturally cool air or water, instead of mechanical refrigeration, to cool the air in a data center.

“More sustainability,” McRay said. “Now you’re not having to use as much energy to cool it down.”

Friedrich Air Conditioning

When it comes to decarbonization and electrification, Friedrich Air Conditioning Co. has a serious head start.

The company has a long history of making only electricity-powered products, not those that directly burn fossil fuels like natural gas and fuel oil.

“Friedrich is a good fit” for the electrification and decarbonization movements, said Jerad Adams, senior manager of product management at Friedrich, “just because of the incredible heat-pump technology, and where we’ve taken the side-discharge heat pump and expanded it into the unitary one-to-one. … So, very earth-friendly, very environmentally friendly.”

The company recently introduced its Breeze line of residential heat pumps with inverter compressors, which help the units achieve efficiency ratings of up to 19 SEER2 and up to 10 HSPF2.

Breeze heat pumps can be paired with many kinds of existing HVAC systems or with third-party air handlers and coils, and Friedrich offers a Breeze Air Handler for optimum system performance. Breeze equipment is compatible with most kinds of 24V thermostats.

VERSATILE HEATING AND COOLING: A Friedrich Air Conditioning Co. Floating Air Pro X heat pump outdoor unit, left, along with a Floating Air Pro X air handler. The system can be mixed and matched with several types of indoor units, both ducted and ductless. (Staff photo)

The Breeze Premier is the most efficient model, available in 2-, 3-, and 4-ton capacities. The Premier is Energy Star cold-climate certified. The Breeze Select is available with 2, 3, 4, or 5 tons of capacity.

Friedrich also offers the Floating Air line of ductless mini-split heat pumps: Floating Air Select, Floating Air Pro, and Floating Air Pro X.

The Floating Air Select is for a single-zone, wall-mounted ductless system and is available in capacities ranging from 9,000 Btuh to 36,000 Btuh, including 115V options, which can facilitate easier installation.

The Floating Air Pro is Friedrich’s highest-efficiency, single-zone wall-mounted line, offered in capacities from 9,000 Btuh to 24,000 Btuh, with a SEER2 rating up to 25. It is also available with 115V options, and all models are Energy Star-certified.

The Floating Air Pro X offers single-zone options from 9,000 Btuh to 36,000 Btuh and multi-zone options from 18,000 Btuh to 42,000 Btuh. This line can heat and cool up to five zones and can be matched with ductless wall-mounted units, cassette units installed in a ceiling, an air handler, or Friedrich’s Insider concealed ducted indoor unit. The Pro X can combine ductless and ducted technology for a hybrid system.

The Pro X is a cold-climate heat pump, offering 100% of its rated capacity at an ambient temperature of 5°F, and is Energy Star-certified.

Adams has one installed at his home, where, he said, it recently stood up to an outdoor temperature of -2°F, keeping the indoors at 65°F without backup heating.

“I was blown away,” Adams said. “The overall operating performance of the heat pump technology now is stunning. It’s incredible.”