During power outages or when experiencing a higher energy demand, industrial power generators will supply power without disrupting operations. The right generator can affect the reliability of the power supply, operational costs, and even project timelines. Below are six vital features to look for when selecting an industrial power generator that meets your operational needs.

Fuel Type and Environmental Considerations

Industrial generators commonly run on diesel, natural gas, or renewable energy sources. Diesel generators are known for their durability and high power output, making them reliable in demanding situations. Natural gas generators tend to be cleaner and could be more environmentally friendly, a top consideration in many industries. When looking for powerful diesel generator options, be aware of your operational needs and the fuel infrastructure you have in place. Evaluate the fuel supply, proximity to refueling, and overall fuel efficiency to save businesses money over time and reduce environmental impact.

You can even integrate hybrid solutions that combine different fuel types. They mitigate fuel cost fluctuations and adjust the energy output based on demand. This flexibility is particularly useful in large-scale industrial applications that require varying energy levels.

Size and Power Rating

Evaluate if the size and power rating of a generator can handle the electrical load required by your operations. Power ratings are expressed in kilowatts (kW) or megawatts (MW). Accurately assess the total wattage your facility requires; improperly sized generators can cause inefficiencies, increased costs, and potential damage to equipment. Consult with a professional to determine your specific power needs based on peak demand and the loads that must remain operational during an outage.

Compact models may be advantageous for businesses with limited space, while larger units provide more power and can serve multiple applications. Look into noise levels, ease of mobility, and user-friendly controls. Improvements in design and technology mean that you can expect massive energy outputs even in smaller units.

Control Systems and Monitoring Technologies

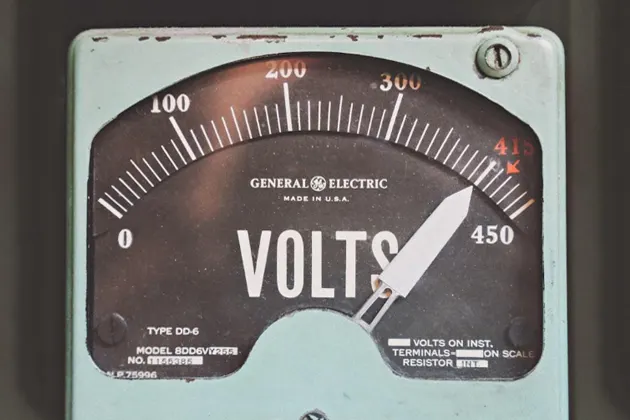

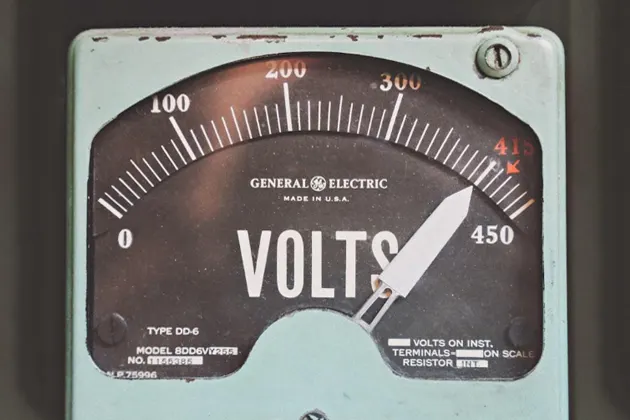

Modern industrial generators come equipped with advanced control systems that offer real-time monitoring, remote operation, and diagnostics. These technologies enable users to make informed decisions about maintenance and performance. Most generators have intuitive interfaces that provide crucial data such as fuel consumption, operating hours, and voltage output and allow for efficient management and troubleshooting.

Remote monitoring capabilities improve operational efficiency by allowing personnel to track performance and adjust settings from any location. Advanced prognostics can alert users to potential issues before they escalate into costly repairs. A generator with these capabilities minimizes operational disruptions and optimizes fuel consumption.

Durability and Build Quality

Durability is a fundamental feature to examine when purchasing an industrial generator. The build quality of the generator should withstand harsh environments, such as extreme temperatures or weather conditions. Equipping the generator with protective features like weatherproof enclosures or sound attenuation can extend its lifespan and reduce maintenance costs. Understand the materials used in the construction of the enclosure, motor, and fuel systems to gauge the expected durability.

High-quality materials will guarantee that the generator can handle rough handling and outside elements. A longer warranty period may indicate that the manufacturer stands behind the product’s durability and provides more assurance for the investment.

Maintenance and Serviceability

A reliable power generator should have a maintenance-friendly design for easy access to frequently serviced components. This can include oil filters, fuel filters, air filters, and other essential parts that require regular changes. Inspecting the availability of replacement parts and the service schedule outlined by the manufacturer is also a necessity before making a purchase decision. Regular maintenance keeps the generator running efficiently and extends its operational lifespan.

Some manufacturers offer service contracts that include preventive maintenance checks so that your generator remains in top condition. Others even provide training for on-site personnel to conduct routine checks and minor repairs. Select a generator that allows easy accessibility for both service crews and in-house staff to reduce downtime and ensure its reliability in times of need.

Compliance and Safety Features

Any generator should comply with industry regulations and safety standards. Compliance assures that the equipment meets necessary safety protocols and environmental requirements, reducing liabilities for your business. Many generators come with built-in safety features like automatic shutdown in case of faults, overheating, or fuel leaks. These features can protect both the generator and surrounding equipment from damage.

Local regulations can ascertain the necessary permits and compliance requirements for operation. Factor in the implications of generator location. Safety distances from structures or potential noise levels should be evaluated early in the planning stages to ensure compliance. Overlooking these details can result in fines or operational halts and incorporate compliance considerations into the generator selection process.

Selecting the right industrial power generator goes beyond simply selecting a unit to produce electricity. By focusing on fuel type, size, control systems, durability, maintenance, and compliance, businesses can make better decisions. A well-chosen generator fulfills the immediate power needs and stands the test of time.